Choosing an aquarium for your home often feels like a purely aesthetic decision, a choice between sizes, shapes, and styles. Yet, beneath the surface of this choice lies a powerful and relentless force: hydrostatic pressure, the weight of water constantly pushing outwards against the glass walls. Understanding the fundamental physics of how this pressure is calculated and managed by manufacturers is crucial for appreciating the engineering that makes a beautiful home aquarium both possible and safe.

This is not a matter of guesswork, but of precise scientific calculation. The formula for determining the pressure exerted on a specific point is P = ρgh, where P is pressure, ρ (rho) is the density of the water, g is the acceleration due to gravity, and h is the height of the water column above that point. This simple equation governs the structural integrity of every aquarium, dictating the required glass thickness and the strength of the silicone seams that hold it all together.

This principle of calculating force and resistance is a cornerstone of safe design in many fields. It requires a deep understanding of materials and the stresses they endure. A similar level of foundational knowledge is needed when delving into the biological sciences, such as when one studies the critical process of osmotic shock in fish, where internal and external pressures must also be carefully managed for survival.

The Unseen Force of Water

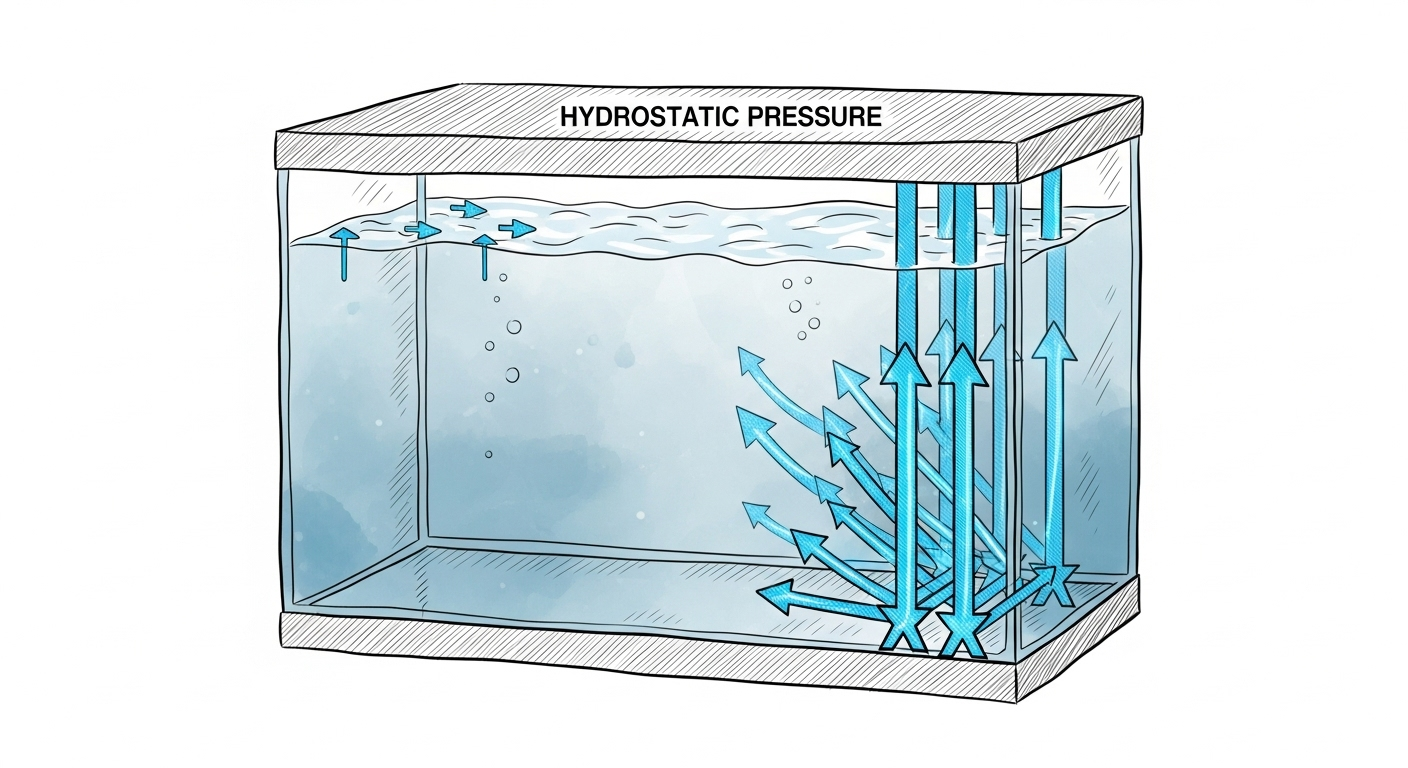

The most counterintuitive aspect of hydrostatic pressure is that it is dependent on the height of the water, not the total volume. This means a tall, narrow aquarium can exert just as much pressure at its base as a much wider, larger-volume tank of the same height. This is because the pressure at any given point is caused by the weight of the column of water directly above it, pushing down.

This force is not just directed downwards; it pushes outwards in all directions with equal strength, a principle known as Pascal’s Law. This means the bottom of the front glass panel is under the same immense pressure as the center of the bottom panel. The outward-pushing force is what places the greatest stress on the aquarium’s seams, particularly at the bottom corners where the pressure is at its maximum.

For this reason, manufacturers use a significant safety factor when designing their tanks. The chosen glass thickness is always far greater than what is minimally required to withstand the calculated pressure. This accounts for minor imperfections in the glass, potential impacts, and the long-term stress that the material will endure over many years of continuous use.

The Role of Glass Thickness

The thickness of the glass is the primary variable that manufacturers use to counteract the immense force of the water. The relationship between water height and required glass thickness is not linear; it is exponential. Doubling the height of an aquarium more than doubles the required thickness and strength of the glass needed to contain it safely.

This is why tall aquariums are significantly more expensive and harder to find than long, shallow ones of the same gallonage. The engineering challenge and material cost increase dramatically with height.

- Standard Float Glass: Most commercially available aquariums are made from standard float glass, which is strong, clear, and cost-effective.

- Tempered Glass: Some manufacturers use tempered glass for the bottom panel of larger tanks. Tempering is a heat-treatment process that makes the glass four to five times stronger than standard float glass, but it cannot be cut or drilled after tempering.

- Safety Factor: A typical safety factor used in aquarium design is around 3.8, meaning the glass is rated to withstand 3.8 times the calculated pressure it will experience.

- Bracing: For very large or tall tanks, plastic or glass braces are added to the top of the aquarium to prevent the long panels from bowing outwards over time under the constant pressure.

Understanding these factors helps a consumer appreciate why a 120-gallon “tall” tank might be constructed more robustly and cost more than a 120-gallon “long” tank.

Silicone: The Flexible Hero

While the glass provides the rigid structure, it is the silicone sealant that acts as the flexible yet incredibly strong “glue” holding the entire system together. The seams of an aquarium are its most critical and potentially vulnerable points. The specific type of silicone used is a 100% silicone material designed for high-strength applications, which cures by reacting with moisture in the air.

The strength of a silicone seam is not just in its chemical composition, but in its application. A properly constructed seam has a specific triangular profile on the inside of the tank. This shape is designed to distribute the pressure evenly along the length of the seam, preventing stress from concentrating in one weak spot. The quality of this bead is a hallmark of a well-built aquarium.

Over time, silicone can degrade, particularly if exposed to certain chemicals, direct sunlight, or physical damage from scrapers. This is why it is crucial to inspect the seams of an older aquarium regularly for any signs of peeling, bubbling, or pulling away from the glass. A compromised seam is the most common cause of catastrophic tank failure.

The Engineering of a Rimless Tank

The trend toward rimless aquariums, which lack the traditional plastic top and bottom frames, represents a triumph of modern engineering and materials science. To achieve this clean, minimalist aesthetic, manufacturers must compensate for the structural support that the frame would normally provide. This is accomplished primarily through the use of significantly thicker glass.

The absence of a top brace means the glass panels themselves must be rigid enough to resist bowing under pressure on their own. This is why a rimless 100-gallon tank will have much thicker glass than a standard framed 100-gallon tank. The increased glass thickness is a direct trade-off for the minimalist design, adding to the cost and weight of the aquarium.

Furthermore, the silicone seams on a rimless tank are often crafted with even greater precision, as they are fully visible and part of the tank’s aesthetic appeal. The clean, perfectly straight lines and bubble-free application of the silicone on a high-end rimless tank are a testament to the skill of its manufacturer, blending high-strength engineering with visual artistry.

Frequently Asked Questions

Generally, yes. Thicker glass provides a higher safety factor and is less prone to bowing or breaking. For any given tank size, a model built with thicker glass is a more robust and safer choice, though it will also be heavier and more expensive.

Absolutely not. You must use a 100% silicone sealant that is specifically labeled as “aquarium safe.” Silicones designed for household use often contain anti-mildew chemicals and other additives that are highly toxic to fish and aquatic life. Using the wrong type of silicone can be fatal for your tank’s inhabitants.

This is called a center brace. On very long aquariums (typically four feet or longer), the front and back panels of glass can start to bow outwards in the middle over time due to the constant water pressure. The center brace connects the front and back panels, preventing this bowing and providing critical structural support to maintain the tank’s integrity.